Select SDGs to find out how we are taking action in support of the UN Substinable Development Goals

-

ICL @ A Glance

-

Vision

Vision & Commitments

Start this Chapter -

Our Business

Our Business

Start this Chapter -

Sustainable Solutions

Sustainable Solutions

Start this Chapter -

Governance

Governance

Start this Chapter -

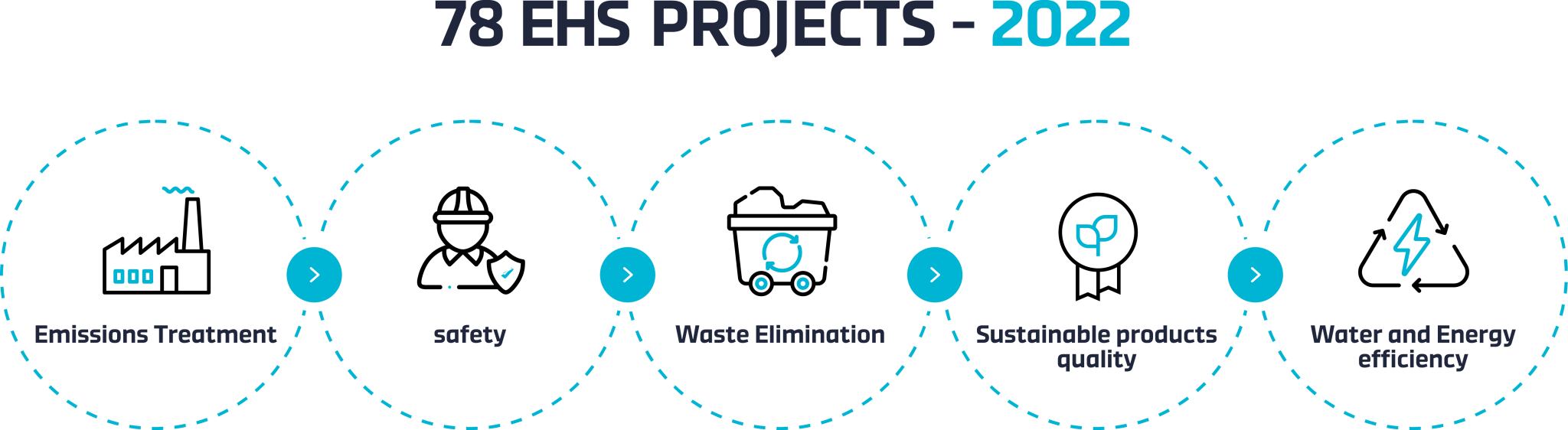

Environmental Performance

Environmental Performance

Start this Chapter -

Our People

Our People

Start this Chapter - Our Communities