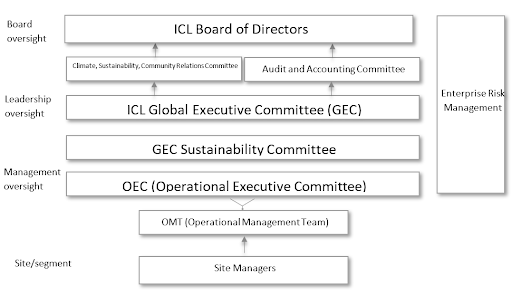

With respect to Board level oversight, our Climate, Sustainability and Community Relations Committee (CSC Committee) is responsible for ICL’s water management, including oversight of achieving water savings targets, implementing water management programs & policies, and overall water stewardship and performance. In addition, our Audit & Accounting Committee oversees ERM water-related aspects.

Regarding executive management level oversight, the Potash Division’s President is responsible for ICL’s overall water management (as acting operational officer in this respect) and has functional and operational oversight over water management strategy and performance in all ICL.

ICL’s OEC (Operational Executive Committee) – Including all OMT Sustainability and Global risk leaders and chaired by our Potash Division President, coordinates all of ICL’s water-related topics, including risk management, and reports periodically to the GEC Sustainability Committee.

OMT (Operational Management Team) – each division holds a monthly meeting to discuss operational performance that includes water related topics, such as resources and usage, current & future balance, operation vs. targets, cross division initiatives to optimize water consumption and others. OMT leaders (at the VP level) report to the OEC on a quarterly basis.

Site Managers collect data on a site level and provide it regarding actual performance and planned consumption, as well as implementing the water optimization policy, suggesting new initiatives and implementing site relevant KPI’s and programs.

As major production sites install new air emission filters and scrubbers that require water as part of their standard operation, ICL expects its water consumption to increase somewhat in the next few years. ICL is actively mapping potential water-saving projects, especially concerning freshwater. The ACE program, which was focused on energy-saving projects, has been given a broader mandate and is now focused on water and carbon emissions as well.

ICL management has declared water reduction goals across all our operations and programs to reduce water consumption have been initiated.

We are taking a systematic approach to reduce our water consumption across our global operations. ESG KPIs and targets, including water reduction targets, have been embedded in executive measures for success and financial performance-based benefits for key executives.