Flame-retardants are designed to delay the ignition of an actual flame, extending the time between smoldering and the start of a fire. This crucial delay provides valuable moments for fire suppression, allowing for the fire to be extinguished more effectively or giving individuals a greater chance to reach safely.

Bromine is used extensively in flame-retardants and ICL supplies bromine and bromine derivatives for these life-saving products. ICL Industrial Products is making significant breakthroughs in the marketplace by expanding its sustainable and efficient flame-retardants portfolio. ICL is continuously developing safe, cost-efficient, and sustainable flame retardants, including innovative and environmentally friendly polymeric and reactive products used in electronics, electrical devices, passenger vehicles, fabrics, textiles, paints, ceramics, foams, lagging, upholstery, mattresses, carpets, curtains, blinds, and many other applications. Our innovative polymeric backbone based products provide superior fire safety benefits without potential environmental drawbacks.

ICL is a leading producer of flame-retardants widely used for building and construction materials. Our flame retardants are used to raise the threshold temperature at which a material ignites, reduce the rate at which materials burn, and minimize the spread of flames.

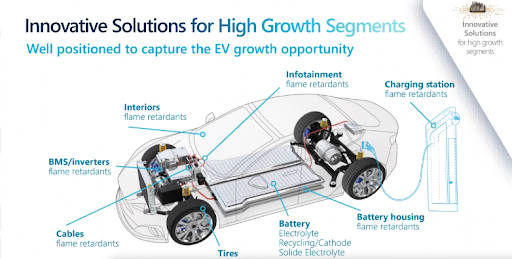

ICL offers more than fifty different flame-retardant solutions for various applications in the automotive and transportation industries, addressing the growing need for more fire safety. Focusing on Electrical and New Energy Vehicles, we offer solutions for highly demanding applications such as powertrains, charging stations, battery casings and covers, wires, cables, connectors, and relays. In mass transportation, our flame retardants are used principally in the cabin compartment in ceilings, walls, seats, trays, and other structures, including in the aircraft industry.

ICL manufactures a wide range of flame retardants for Electrical and Electronic (E&E) applications, preventing fatal electrical fire accidents and damage to property or the environment. Our flame retardants also meet or exceed the industry’s most stringent environmental guidelines and are used, among others, in circuits, insulation, casings, housings, and cables. Applications include TVs, computers, servers, white goods, printed circuit boards, connectors, relays and more.

Read more about the multiple applications of ICL’s fire retardants.